1. Installation instructions. The use of steering oil pump: choose the right oil pump according to the vehicle performance requirements and power steering gear basic parameters.

2, the use of oil should be full of rudder steering system according to standard solution. 26 square millimeter / second gear oil viscosity (temperature 50 degree C), the recommended freezing point is less than -35 degree C. Dexron or Mercon-M and recommended standards. The oil temperature of the power steering device should be at -40 degree C and 120 degree C.

3, filter: net pressure filter.

4, when the power steering gear is installed, it is not used to adjust it.

Note: the tubing should be installed correctly. Do not confuse import and export, otherwise the power steering device will be damaged. Keep the internal cleaning of the power steering gear. The power steering device is driven by the oil pump's automobile engine, so the car can't slide when it is out of fire, otherwise it will cause the steering problem. Drivers can't limit the power steering device to more than 5 seconds. Please take it as your limit, otherwise the oil pump may be damaged. The spool is adjusted to the best condition, and the rest should not be removed. When oil seal and garbage ring are removed, repair should not be used again. Oil refuel should be the same as the original. If the hydraulic system is broken and can't work, the driver should increase the power to turn the car for the time being. When assembling and disassembling the power steering system, please do not strike or be intense. Please keep clean and prohibit any foreign material steering system.

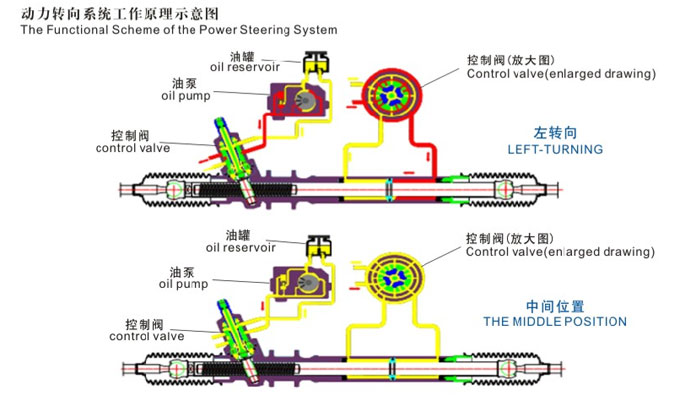

1. Power steering principle.

A hydraulic device that USES the engine to power the steering. Namely according to help the engine driven hydraulic pump, hydraulic and effect on the power cylinder piston, to make the pinion and rack to a support force, the size of the auxiliary power and function is related to the pressure on the piston. Therefore, the need for greater steering force must be increased. The hydraulic change is controlled by a control valve connected to the steering spindle.

2. Power steering function.

Reduce the operating force on the steering wheel when the car turns; Limit the deceleration of the steering system; To provide the necessary assistants when turning in place; The steering sensitivity is high, the control is light, the force of the steering wheel is small, and the labor intensity of the driver is reduced. Limit the vehicle speed to have better steering stability; When the steering device fails, the mechanical steering system can be maintained effectively. It can absorb the impact of the road on the front wheels, and reduce the anti-impact and "hand-to-hand phenomenon" of the steering wheel. (power steering system consists of steering tank, steering pump, steering pipe and power steering.)

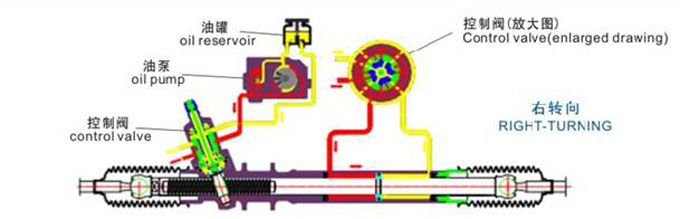

3. The power steering is the rotary valve structure (hydraulic directional machine)

It is generally performed by rotating the engine with the engine, and the oil is pumped out of the tank to the power steering valve. When the control valve is in the middle of the normal opening, the oil is directly returned to the steering tank through the control valve.

1. Middle position

Car straight line driving (steering wheel fixed), oil pump to supply hydraulic oil from the oil inlet, after rotary valve of pre-opening gap. Flow around two working chamber, because the rotary valve, thus working hydraulic steering gear two same does not produce power, the hydraulic oil from the oil return back to the tank mouth, see the principle diagram of the gear and rack type power steering gear.

2. Steering process

When turning the steering wheel, the pre-opening gap between the input shaft and the valve sleeve changes, resulting in the oil pressure difference between the hydraulic oil flowing to the two working chamber and the steering resistance. The oil pressure difference is used to push the rack piston on the rack piston to overcome the steering resistance and produce the displacement, thus driving the steering rod to realize the front wheel steering.

3. Return process

When the steering is completed, the force on the steering wheel disappears. Torsion bar within the power steering gear and the car front wheel automatically back to the positive moment, under the action of two poor working oil chamber of hydraulic steering disappear, sports steering wheel to the straight position, until back to the car driving straight position.

4. Road sense effect

The road sense effect is the ability to turn to feeling. When the driver forces on the steering wheel, it also ACTS on the torsion bar on the steering gear to produce torsional deformation; The deformation depends on the steering resistance of the wheel. When the steering resistance is large, the deformation is also increased. Therefore, the driver can judge the change of the steering resistance according to the size of the force on the steering wheel, so as to obtain the "road sense" effect.

Principle of the steering mechanism (as shown in the figure)

The steering gear is pinion, and the back of the gear has an adjusting semicircle, which is pressed against the rack by spring pressure, so that the rack is always in contact with the pinion with appropriate force. The clearance of the steering mechanism is the adjustment of the semicircle and spring automatically on the lower side of the rack.

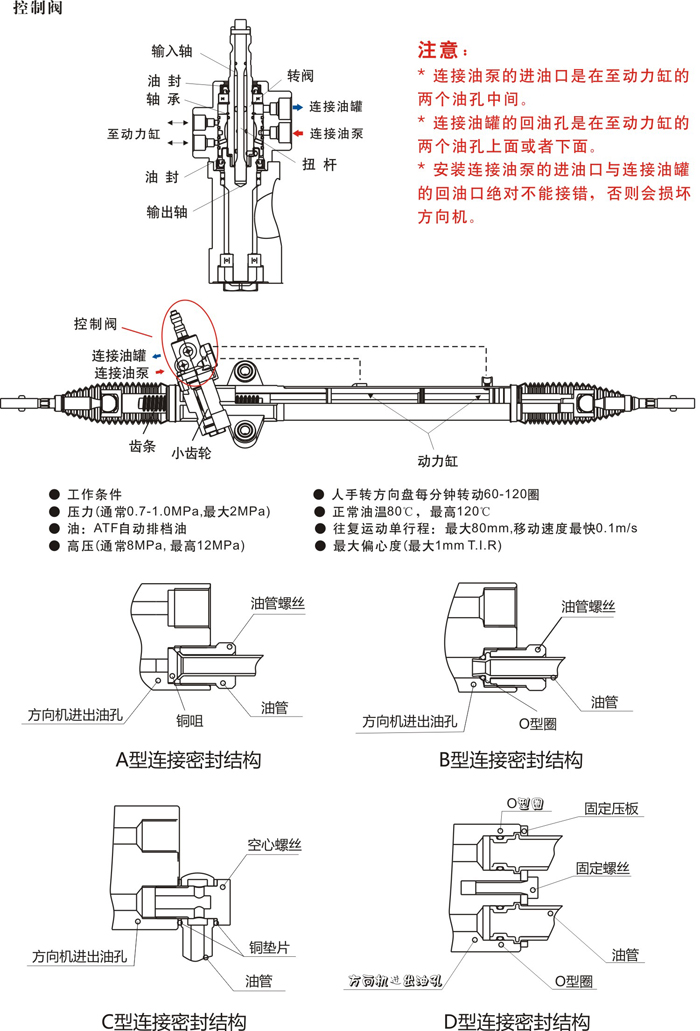

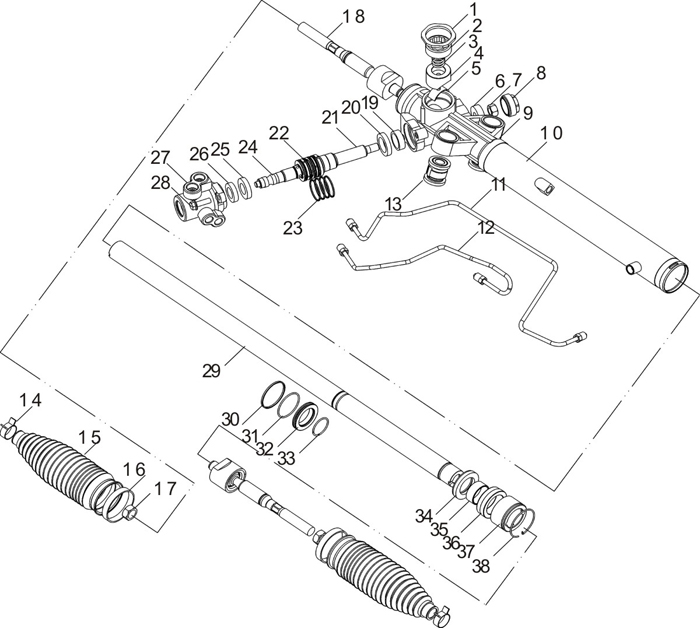

Schematic diagram of structure principle of gear rack power steering device.

1, 2, adjusting screw adjusting nut 3, 4, adjusting spring adjustment round 5, round gasket 6, 7, end cover nut shell bearing under 8, end cover screw 9, 10, 11 oil cylinder assembly, shell under long tubing 12, short tubing 13, 14 15, rack, coupling assembly machine foot dust cover 16, 17, 18, inner tie rod nut bar hoop assembly (19, 20, valve, valve gear bearing oil seal, valve 21 tooth 22, 23 body, the body king plastic ring on the 24, 25, valve core bearing shell, shell oil seal on 26 and 27, 28, up and down on the shell shell connecting screws, 29, 30, piston rack and plastic ring king 31 32, piston, piston o-rings, 33, live chandrasekhar spring 36, 34, 35, sliding bearing high pressure oil seal oil cylinder oil seal 37, oil cylinder oil seal iron iron set 1 set of 2 38, cylinder spring

Its main structural parameters are as follows:

Ex. :

|

Transmission ratio |

46.67 |

|

Center distance |

20mm |

|

Rotational total winding number |

3.3±0.1 |

|

trip |

158mm |

|

Module of gear |

1.85 |

|

Gear train to |

Left |

| Maximum working oil pressure. | 8.5Mpa |

|

The input torque |

4-6N.m |

|

The output |

8157N |

|

Commonly used bore |

Rack diameter |

|

Φ35、Φ36、Φ38、 Φ39、Φ40、Φ41、 Φ42、Φ42.5、Φ43、 Φ43.5、Φ44、Φ45、 Φ46、Φ48、Φ49、 Φ50、Φ52、Φ53、 Φ55、Φ56 |

Φ22、Φ23、Φ24、 Φ25、Φ26、Φ27、 Φ27.7、Φ28、 Φ30、 Φ32、Φ35、 Φ38 |

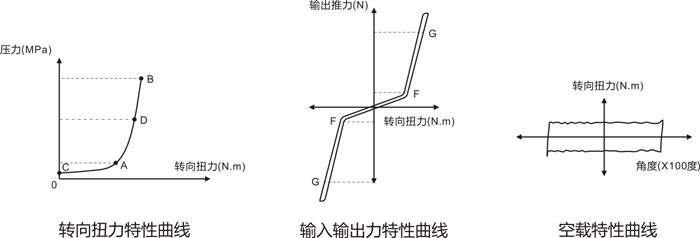

The transmission characteristics of gear rack type steering gear.

The gear rack type steering device has simple structure, convenient manufacturing process, high transmission efficiency and complete sealing device, so it is reliable. It is widely used in early foreign passenger cars, but because of the smaller transmission ratio and limited use, there is more use in the micro cars. In the pinion type steering gear, the steering shaft ends with a helical cylindrical gear, which is engaged with the rack mounted on the shell, and the shell is fixed on the frame. The rack is connected by two ball joints and two separate tie rods, which directly drive the bar and turn the car.

Gear and rack type steering gear in use, when the parts wear a gap, by compensating the spring pre-tightening force of clamp platen, remain the best meshing state to keep the gear and rack, so that the steering wheel in a proper swimming clearance, improve control sensitivity.

5. Advantages of pinion and rack type steering gear.

Adopt gear rack type steering, because do not turn rocker arm shaft and rocker arm and so on parts, the structure is simple, easy to arrange, the craft is convenient, and the service life is long, the transmission is reliable. Therefore, it is widely used in the light and micro cars with the front wheel independent suspension.

Vi. Installation instructions.

1. Use of steering pump:

According to the performance requirements of the vehicle and the basic parameters of the power steering gear, the oil pump is reasonably selected.

2. Working oil:

The steering system should be added to the steering fluid by standard. Suggest a viscosity of about 26 was/S (under the condition of 50 ℃), below the freezing point - 35 ℃, automotive automatic transmission oil with low foam properties. Recommended standard for the oil: Dexron Ⅲ or Mercon - M. The oil temperature in the range of power steering system to 40 ℃ ~ 120 ℃. (with no Dexron or mercon-m oil, you can use no. 8 hydraulic transmission oil instead.)

3. Filter: mesh filter.

4. When the power steering is installed, the steering device itself does not need to be adjusted.

Matters needing attention

* the inlet and outlet of the steering pipe should not be wrongly installed, otherwise the power steering will be damaged.

* the power steering system must be kept clean.

* the steering gear is powered by a car engine, so the car is not allowed to flameout. Otherwise, it will lead to heavy steering, which is prone to accidents.

* during operation, the steering wheel should be avoided to the limit position, generally not exceeding 5 seconds. At this time, the steering wheel should be rotated slightly, otherwise the oil pump will be easily damaged, affecting the life of the steering system.

* the valve core assembly has been adjusted to the optimum state, and the cylinder pins and other parts shall not be disassembled.

* the sealing parts such as oil seal and sealing ring removed during maintenance shall not be used again.

* when the hydraulic oil is added, the new hydraulic oil should be consistent with the original hydraulic oil brand of the power steering system, and it is strictly prohibited to mix oil.

* if the hydraulic system fails to work properly, the driver will only need to increase his hand power and can still rely on the mechanical steering to realize the steering of the car.

* the maintenance and maintenance of power steering gear should be carried out at our company's service station.

* when loading and removing the steering system, it is strictly forbidden to knock or impact with any force, and should be taken lightly. When assembling, it must be cleaned, and no impurities are allowed to enter the steering system.

Proper use and maintenance of power steering system.

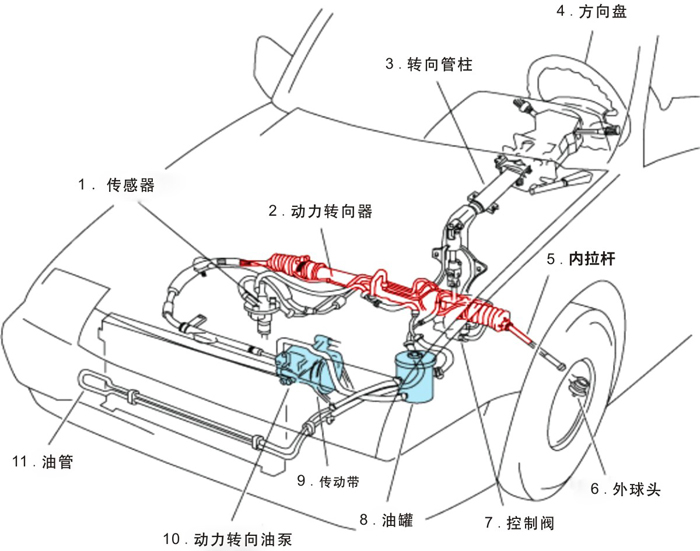

Power steering system installation diagram.

Vii. Maintenance and maintenance.

1. After driving 2500Km, the new power steering device needs to replace the hydraulic oil and clean the filter in the tank. The hydraulic oil and cleaning filter should be replaced every 50000Km(or one year).

2. Check whether the hydraulic oil quantity is reduced once a month, whether the oil fluid is spoiled or impurities are too much. If the bad condition is found, the hydraulic oil should be added or replaced in time.

3. Always check and keep the tyre pressure in accordance with the regulations.

4. Change (add) oil time program.

(1) raise the front axle.

(2) open the tank cover, and the steering oil outlet bolt unscrewed, out of the oil pump and oil tank oil residue (idle running engine), and the steering wheel to the limit position about play several times, until no more oil outflow oil mouth.

(3) tighten the outlet bolts of the steering gear. (keep clean to prevent dirt and foreign bodies from entering the oil system)

(4) inject new hydraulic oil into the tank.

(5) idle running engine, turn left and right to the limit position several times until the oil surface of the oil tank no longer drops and no bubble is produced.

(6) the replenishment of the oil can make the oil surface of the tank reach the mark.

(7) tighten the tank top.

8. Common failures and troubleshooting methods.

Any failure of the steering system will affect the safety of the vehicle and may cause driving failure, and the steering system must be checked frequently.

|

The fault |

The main causes. |

Elimination method |

|

To difficult |

The tyre pressure is low and the engine speed is not steady. |

Inflate the tyre and adjust the performance of the engine. |

|

The main pin Angle is too large. |

Check the front wheel alignment. |

|

|

Wear of the steering system universal joint. |

Replace the steering system universal joint. |

|

|

Lower arm ball socket wear. |

Replace the lower arm ball socket. |

|

|

The steering column is stuck. |

Check the steering column. |

|

| The piston cylinder of the steering gear is too worn, the oil seal is poor, and the rotary valve is stuck. |

Repair the steering gear. |

|

|

The oil pump is too low. |

Replace the oil pump |

|

|

Heavy vehicle overload |

lightening |

|

|

There is foreign body in the steering system to cause the steering pump flow control valve lag. |

Check the steering gear, steering pump control valve and clean the entire power steering system. The inside of the oil cup is too dirty, the filter is blocked or the oil cup is low, it is necessary to replace the oil cup. |

|

|

The belt of pump is loose, sliding or pump mounting position is loose. |

Adjust the tension of the belt as required. Fastening the connecting screw for each part. |

|

|

There is air in the power steering system. |

Provide air to the steering system as required. |

|

|

The bolts of the connecting parts of the tubing are loose, causing the diversion fluid leakage. |

Check the connection parts of the tubing, Tighten each connection bolt. |

|

|

Unilateral steering heavy |

Unilateral tire pressure is not enough. |

inflatable |

|

The diverter leaks only in one direction. |

Repair the steering gear. |

|

|

The rotary valve is not in the middle position. |

||

|

Left or right fixed pressure can't be built. |

Replacement of seals |

|

|

Hit both sides quickly. Steering wheel heavy |

Turn to oil outlet and turn to oil pump. Inlet and steering pump and engine. The joints of the air are drawn in. |

Tighten tubing joints or replace seals. |

|

The steering pump flow is too low. |

Change steering pump |

|

|

Steering wheel free travel. Big, jitter |

The steering wheel and steering shaft are loose, The steering gear assembly is too loose. Fixed snails for steering and steering brackets. Bolt looseness |

Tighten the loose part. |

|

Wear of front wheel bearing. |

Replace the front wheel bearing. |

|

|

Main shaft fork or intermediate shaft fork wear. |

Replace the main shaft fork or intermediate shaft. |

|

|

Lower arm ball socket wear. |

Check the lower arm ball socket. |

|

|

Steering rod assembly or outer ball. Head wear |

Replace the steering rod assembly or. Ball head assembly |

|

|

Steering gear maladjusted or damaged. |

Adjust or repair steering gear teeth. |

|

|

The deflector overheats. Environment temperature is above 65 ° C) |

Excessive pump flow |

Replace the oil pump |

|

Tubing bending radius is too small or internal. The resistance causes the fluid to flow poorly and heat. |

Replace the tubing |

|

|

Turn to limit position at both ends for more than 5 seconds. |

Avoid turning to extreme positions at both ends. |

|

|

Steering blanketed |

Steering system components loose or worn. |

Tighten or replace. |

|

The steering tank is lower than the oil mark. |

refuel | |

|

Turn to universal joint locking bolts to loosen. |

Tighten the bolt |

|

|

Negative return |

Steering gear maladjusted or damaged. |

Adjust or repair steering gear. |

|

Power steering strap slack. |

Adjust the belt |

|

|

Low hydraulic oil level in reservoir. |

Check reservoir |

|

| Power steering has trouble check. |

Power steering |

|

|

Improper inflation of tyre |

Inflate the tyre to the specified pressure. |

|

|

Wheel positioning is incorrect. |

Check the front wheel alignment. |

|

|

The steering column is stuck. |

Check the steering column. |

|

| Abnormal noise |

The steering shaft is slack. |

Tighten the steering rod system. |

|

Wear of the steering system universal joint. |

Replace the steering system universal joint. |

|

|

Steering gear maladjusted or damaged. |

Adjust or repair steering gear. |

|

|

The car is on a flat road. The surface is run in two directions. |

The steering wheel head section is loose or the front wheel is improperly positioned. |

Adjust the front wheel alignment and turn the ball head. |

|

The pretension of the rack in the steering gear is misaligned. |

Adjust or maintain the pretensioning of the steering gear. |

|

|

The steering rod is distorted or overworn. |

Replace the steering gear. |

|

| The power steering fluid produces a milky foam. |

There is air in the steering system. |

Remove the air and check for leaks. To solve |

|

There is fluid leakage in the steering system. |

Check the oil cup and lubricate the oil cup. |

|

|

Turn on the noise in the system. |

There is air in the steering system. |

Remove the air and check for leaks. To solve |

| The steering tube has no noise reduction function. |

High and low pressure tubing with noise reduction function. |

|

|

The diverter valve assembly is poor. |

Replace the steering gear. |

|

|

Steering system internal cleanliness, resulting. |

Cleaning and inspecting the tubing, oil cup, oil pump, |

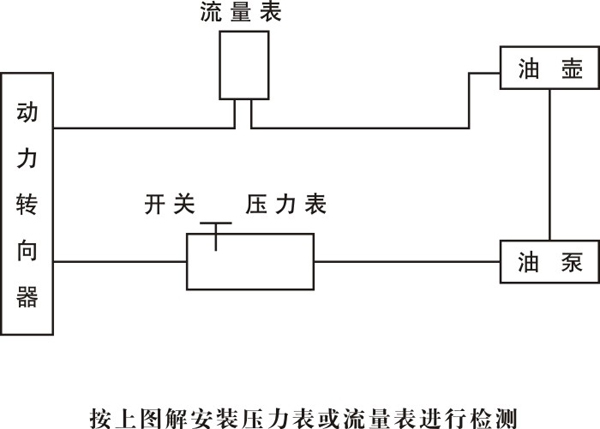

2) check the oil pressure.

The failure of the power steering system is usually related to the difficulty of steering with no auxiliary force. In this case, if it is to be repaired, the first thing to do is to figure out whether the problem is on the pump or on the case. To do this, a pressure gauge can be used to check the car.

1) check the pressure value when the valve is closed.

Close the pressure gauge valve and read the pressure value on the pressure gauge.

Minimum pressure :80 kg/m2 (7.8Mpa)

Note:

Do not allow the valve to be closed for more than 5 seconds in order to avoid the danger of detonating tubing.

Note that the oil temperature should not exceed 80 degrees.

If the pressure is low, the power steering pump should be repaired or replaced.

2) check the pressure difference.

Check and record the pressure value at 1000 RPM.

Check and record the pressure value at 3000 RPM.

When the pressure difference is over 5 kg/m2 (4.9Mpa), the power steering pump should be repaired or replaced.

3) check the rotary valve pressure value of the steering machine.

Make sure the pressure gauge is fully open and the engine idling.

Minimum pressure :80 kg/m2 (7.8Mpa)

Note:

Turn the steering wheel left or right to start the steering valve for no more than 5 seconds.

Low pay attention to the oil temperature is not higher than 80 ℃.

If the pressure is low, there is leakage inside the steering gear, and the power steering should be repaired or replaced.

公司地址:广东省佛山市南海区狮山镇永和村鸪西工业区4号(一汽大众东2公里)

手机号码:189 2864 8619

联系电话:0757-8100 2219

传真号码:0757-8119 9229

电子邮件:SALES@GDDKM.COM

网站共享

Copyright © 2018 广东帝盟汽车零部件有限公司 后台登录 粤ICP备19114395号

技术支持:方维网络